The Sixth Street Bridge was originally constructed to join a city divided. For many years the northern section of the city remained undeveloped, largely due to the Wilmington & Weldon Railroad tracks which divided the city, north from south. The first bridge was of wood, built about 1873. The Wilmington Board of Aldermen ordered the railroad company to construct bridges across the "cut" at Second, Third, Fifth, Sixth, Seventh and McRae streets. At this time only one bridge existed and it was located on Fourth Street and was called the Boney Bridge, but it was considered too narrow for heavy traffic. The bridge on Sixth Street was to be 25 feet wide. In 1866, the Sixth Street Bridge was condemned and a new bridge was built, again of wood. This bridge was rebuilt again in 1891 and 1895. In 1902, the Wilmington Dispatch newspaper reported that "the old wooden bridge over the Coast Line tracks at Sixth street is to be repaired and a contract will be let in about ten days. The bridges will be kept in good repair and when the Fifth Street bridge is finished there will be three "first-class" bridges connecting Brooklyn (the section of the city north of the tracks)."

In December, 1909, the wooden bridge was condemned and removed. The same month, negotiations began for a new bridge constructed of steel with wood floor. In July 1910, an advertisement for bids for a steel bridge at Sixth Street appeared in newspapers. The bids were opened in August 1910, and a contract was let in September. The bid accepted was made by the Southern Construction Company of Burlington, N.C. Its proposal was $7,500.

The contract made with is company proved to be a disaster. From the beginning they had trouble making the required bond and in May 1911, the contractor left town, leaving many of his laborers with wages unpaid. The construction firm also left unpaid bills, among which was a large one with the Des Moines Bridge & Iron Company who supplied the steel for the bridge. The sheriff attached the unfinished bridge and all the materials yet to be used. The press referred to this situation as the "Sixth Street Muddle".

One June 17, 1911, it was announced that A.D. O'Brien, a Wilmington Civil Engineer, had been awarded the contract to complete the bridge on Sixth Street. His bid was $1,400. The bridge was completed in the fall of that year and dedicated."

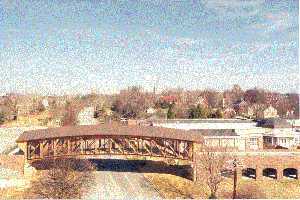

Included in the national Historic American Engineering Record, the bridge has been photographed and recorded for permanent record. Its inclusion attests to its value as an example of the style and to its relative rareness as an area survivor. At one time, all Wilmington streets crossed the railroad tracks on truss bridges of one type or another. This bridge along survives.

The narrowness of the bridge and ramp approaches, which highway engineers are fond of listing as two of its major drawbacks, may also be viewed as part of the value and charm of such bridges. They force us to slow down, and they remind us of the role the railroad played in the development of the area. Vistas from this bridge not only show the deep cuts that the tracks made through Wilmington, but the many commercial and industrial structures along the right-of-way, all railway-oriented. To the northwest, dwelling along the tracks are also visible.